3000w laser welder

TECHNICAL PARAMETER

| LASER SIMBA | 1000W | 1500W | 2000W |

| Kunyungudika kudzika (simbi isina tsvina, 1m/min) | 2.68mm | 3.59mm | 4.57mm |

| Kunyungudika kudzika (carbon simbi, 1m/min) | 2.06mm | 2.77mm | 3.59mm |

| Kunyungudika kudzika (aluminium alloy, 1m/min) | 2mm | 3mm | 4mm |

| Kudyisa otomatiki waya | φ0.8-1.2 welding waya | φ0.8-1.6 welding waya | φ0.8-1.2 welding waya |

| Simba rekushandisa | ≤3kw | ≤4.5kw | ≤6kw |

| Kutonhodza nzira | kutonhora kwemvura | kutonhora kwemvura | kutonhora kwemvura |

| Simba rinodiwa | 220v | 220v kana 380v | 380v |

| Argon kana nitrogen kuchengetedza (mutengi pachake) | 20 L/min | 20 L/min | 20 L/min |

| Equipment size | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Equipment uremu | ≈150kg | ≈170kg | ≈185kg |

Kushandiswa kwehandheld laser welding muchina muindasitiri yeaerospace

Nhanganyaya

Muindasitiri yezvemuchadenga, emhando yepamusoro welding maitiro akakosha pakuona kuchengetedzeka uye kuita kwendege. Mumakore achangopfuura, handheld laser welding michina zvishoma nezvishoma yakawana mukurumbira muindastiri nekuda kwekunaka kwavo kwakasiyana. Ichi chinyorwa chinopa yakadzama sumo yekushandiswa kwehandheld laser welding michina muindasitiri yezvemuchadenga.

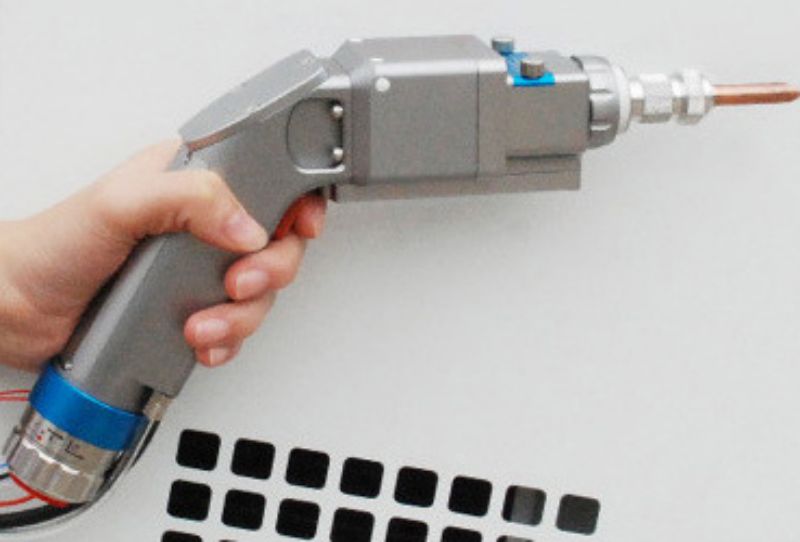

Nhanganyaya kune Handheld Laser Welding Machine

Iyo handheld laser welding muchina ndeye advanced laser welding midziyo inoshandisa yakakwira-simba laser sosi, inofambiswa kuburikidza neoptical fibers, uye yakanangwa uye yakagadziridzwa neyepamberi control system. Iyo handheld laser welding muchina ine zvakanakira kushanda kuri nyore, kuchinjika kwakasimba, kukurumidza welding kumhanya, uye yakakwirira welding mhando.

Kushanda muindasitiri yezvemuchadenga

High quality welding:Iyo handheld laser welding muchina unogona kuwana chaiwo chinangwa uye kugadzirisa, nekudaro kuve nechokwadi chemhando uye nekurongeka kwewelding. Muindasitiri yezvemuchadenga, kutonga kwemhando yewelding kwakakosha, uye kushandiswa kwehandheld laser welding michina inogona kuvandudza zvakanyanya kunaka kwewelding.

Kubudirira:Iyo handheld laser welding muchina unogona kupedzisa emhando yepamusoro-welding mashandiro munguva pfupi yenguva, achinatsiridza zvakanyanya kugadzirwa kwakanaka. Izvi zvakakosha kune indasitiri yezvemuchadenga, sezvo ichida kugadziridzwa kwenhamba yakawanda yezvikamu uye zvikamu, uye maitiro ekugadzira anoshanda akakosha pakuona kunaka uye kufambira mberi kwekugadzira ndege.

Kuchinjika:Handheld laser welding michina ine yakakwirira kuchinjika uye inokwanisa kubata zvakasiyana-siyana zvakaoma welding zvinodiwa. Ingave nzvimbo yewelding, butt welding, kana fillet welding, handheld laser welding michina inogona kuibata zviri nyore. Uku kuchinjika kunopa mabhenefiti makuru mukubata zvikamu zveakasiyana maumbirwo uye saizi.

Kuchinja:The handheld Laser welding machine inogona kuenderana nezvinhu zvakasiyana-siyana zvezvikamu, kusanganisira simbi, isiri-simbi, nezvimwewo. Kuchinja uku kunoita kuti iite basa rinokosha pakubata mhando dzakasiyana dzendege.

Ushamwari kwezvakatipoteredza:Iyo handheld laser welding muchina haiburitse zvinhu zvinokuvadza panguva yewelding process uye inosangana nezvinodiwa zvezvakatipoteredza. Muindasitiri yezvemuchadenga, hushamwari hwezvakatipoteredza chinhu chakakosha kufunga, saka kushandiswa kwehandheld Laser welding machines kunogona kubatsira kuderedza kukanganisa kwezvakatipoteredza.

Mhedziso

Zvakanakira zvehandheld laser welding michina inoita kuti ishande zvakanyanya muindasitiri yemuchadenga. Iyo haingogone kuvandudza kugona kwekugadzira, asi zvakare kubata neyakasiyana yakaoma welding zvinodiwa. Panguva imwecheteyo, hushamwari hwayo hwezvakatipoteredza uye hunhu hwekuchengetedza vashandi hunoitawo kuti ive sarudzo yakanaka kune indasitiri yezvemuchadenga. Nekuenderera mberi kwekuvandudza tekinoroji, kuita uye mashandiro ehandheld laser welding michina ichave zvakare yakavandudzwa nekuvandudzwa, uye mashandisiro avo muindasitiri yezvemuchadenga achavewo akawedzera uye akadzama.

Welding quality kunatsiridza Six welding modes

Inogona kupedzisa zvinodiwa zvekushongedza izvo zvisingakwanisi kupedzwa neakajairika welders, uye weld yakasimba uye yakanaka,Hapana welding slag, isiri nyore ku deformation, dema

Spot welding:diki nzvimbo, simba rakasimba, nzvimbo welding modhi inogona kushandiswa kana zvinhu zvine welding kupinza zvinodiwa;

Mutsara wakatwasuka:hupamhi hunogona kugadziriswa, zvinhu zvine kupinda, mukubatanidza welding, waya yekudyisa welding, Positive fillet welding inogona kushandisa mutsara welding mode;

"O" mhando:inogadziriswa dhayamita, yunifomu kugovera kwesimba density; High frequency kana welding sheet "O" welding inogona kushandiswa;

Kaviri "O":inogadzirika dhayamita, kuderedza chiedza chivara, chakakodzera welding pamakona akasiyana;

Triangle:Upamhi hunogona kugadziridzwa kuderedza nzvimbo yechiedza nepo simba remapendero matatu rakafanana. Pakati uye mativi ose eplate anonyatsopisa;

"8" izwi:ramba uchiwedzera chiedza chechiedza pahwaro hwetatu, kuitira kuti ndiro inodzokororwa inopisa, yakakura.

Iyo "8" pateni inogona kushandiswa pahupamhi welding.

Packing & Shipping

Muchina uyu waizorongedzerwa mukrete remapuranga rakasimba rekutumira kune dzimwe nyika, rakakodzera kugungwa, mhepo uye zvekufambisa.